Haitian Precision BEL/BFL High-speed Gantry Machining Center

2022-07-20

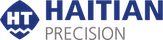

With a huge volume and complex system, the battery pack of new energy vehicle needs a solid shell to protect. The battery chassis, located at the bottom of the whole battery pack, playing the role of supporting the battery pack, can be said to be the protective part of the “heart” of new energy vehicles, with high requirements in structural design and weight.

The battery chassis is a large-area thin-walled material, which is easy to deform during processing, and has high requirements for sealing performance. Therefore, the processing equipment is required to have high precision and high rigidity processing performance. At the same time, due to the large area to be processed, the processing efficiency of the equipment shall also be considered.

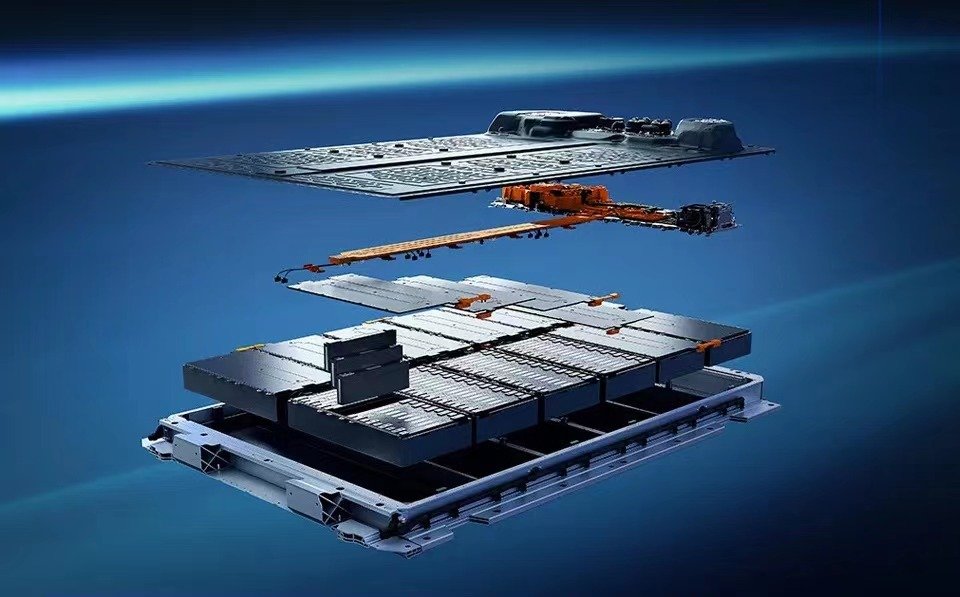

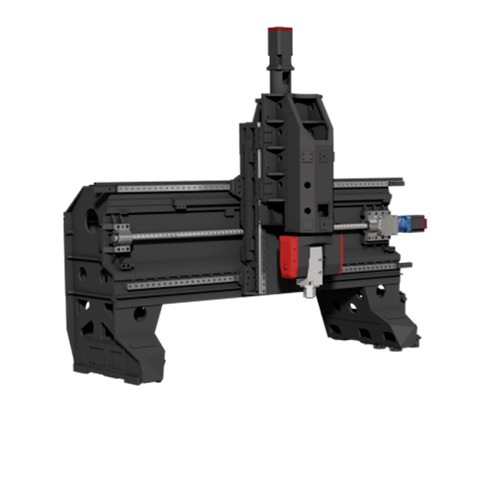

BEL/BFL2018/2030 high-speed gantry machining center mainly used in the processing of battery trays, integrated die-casting door panels and other parts on new energy vehicles is built with the gantry machine tool foundation frame which has the advantages of strong rigidity, symmetrical structure and strong stability. In this way, five-axis machining can be realized, and multi-angle feature machining can be completed by one clamping to improve the overall machining efficiency of parts, ensure the consistency of machining accuracy of parts, and reduce the scrap rate.

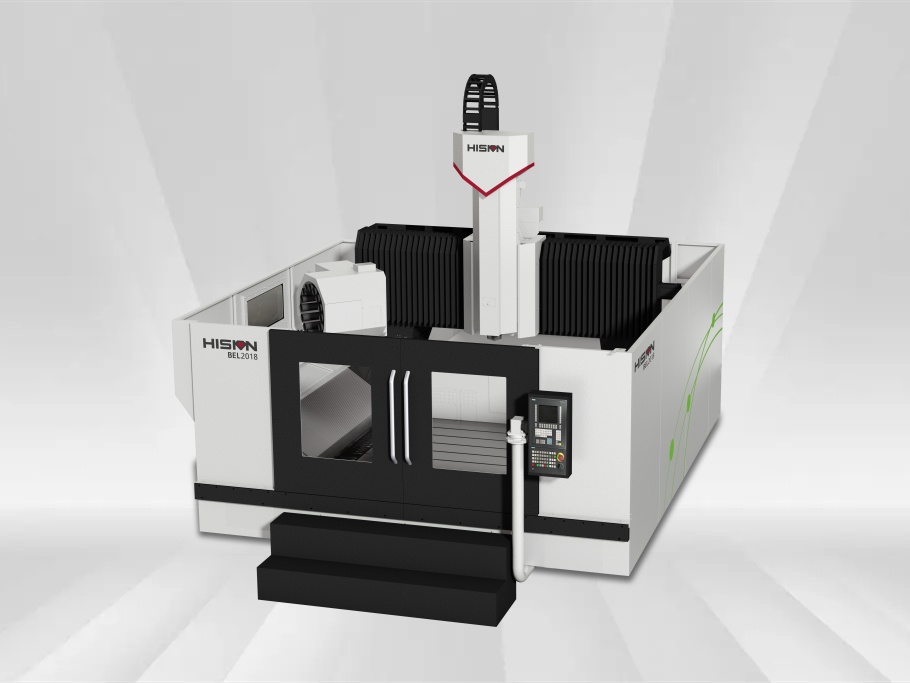

The A/C swing head can be retracted into the saddle to shorten the height of the column beam and improve the rigidity of the machine tool.

The beam-column gantry frame is a high-speed moving structure to reduce the connection links.

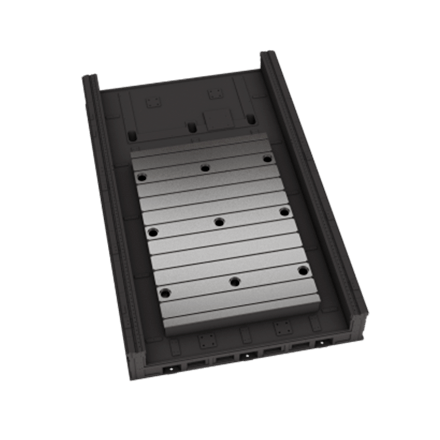

The machine bed workbench is cast integrally to improve the accuracy stability of the whole machine.